For heavy truck air filters

Filter adhesive plays an important role in air, oil, water and HVAC filter assembly and manufacturing. Given the vital role of adhesive in the filter production, using the right adhesive makes a big difference in filter assembly and manufacturing.

How to choose the best adhesive for your applications? PLM would like to provide some basic information of our 4 types of filter adhesives to help you to understand and select the right adhesive for your specific application in filter manufacturing process.

PU adhesive

Two component filter cartridge adhesive

One component thermosetting adhesive

Hot melt glue

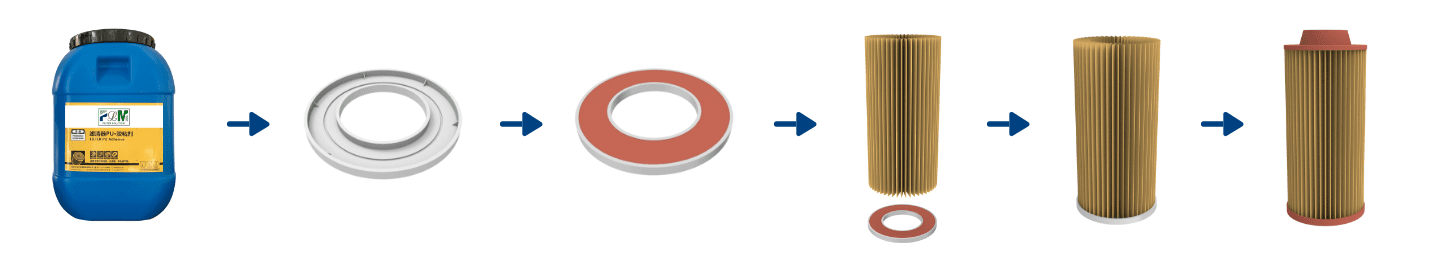

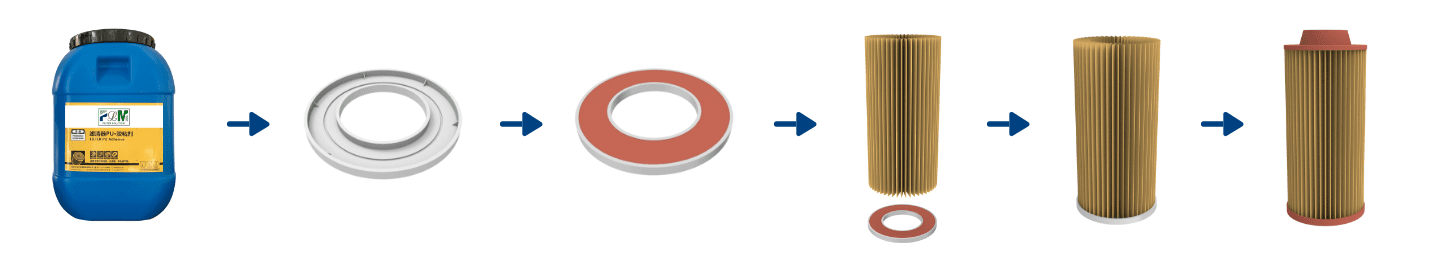

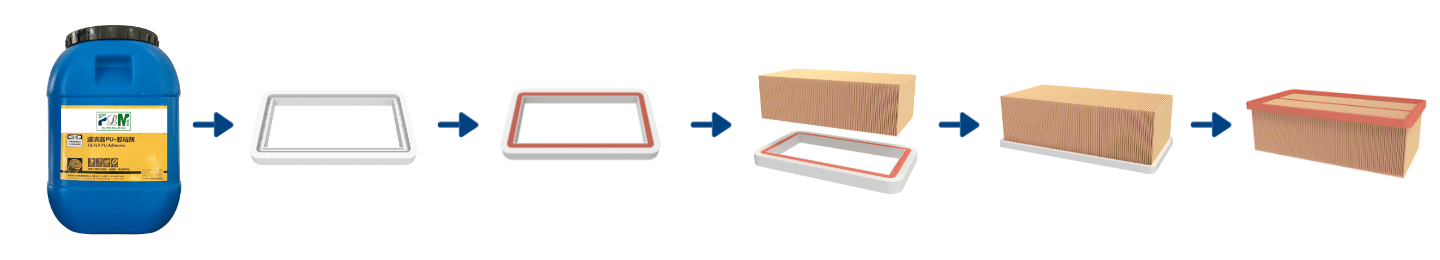

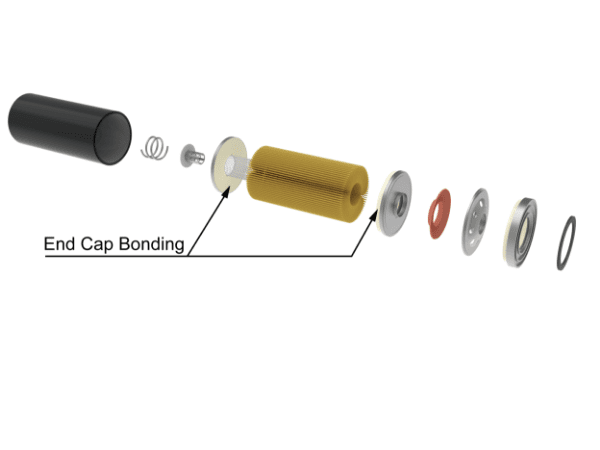

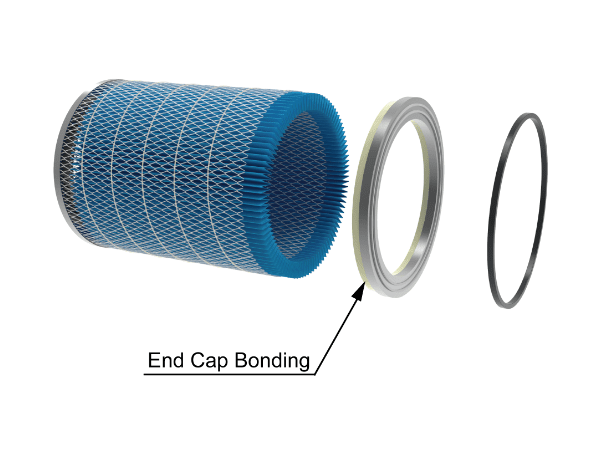

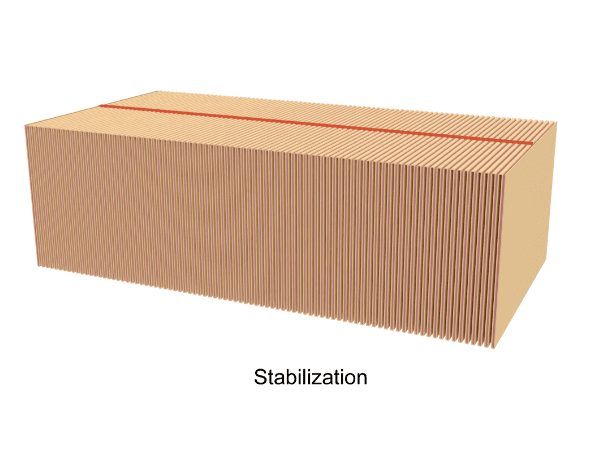

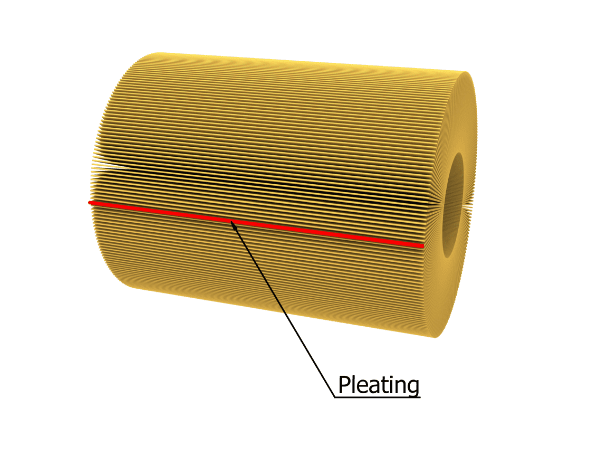

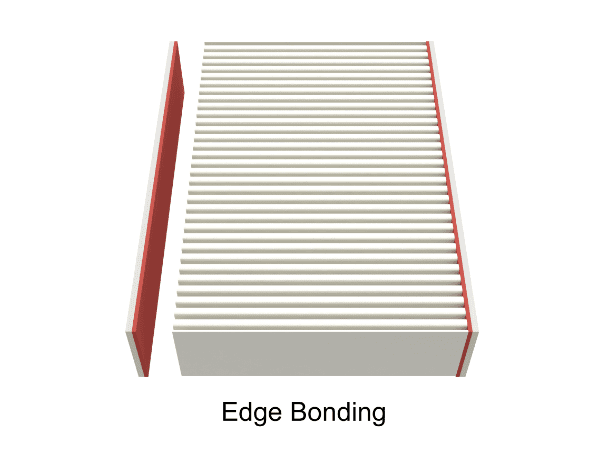

Filter adhesives are often used to fabricate numerous filter components, to assemble the filter media itself, to bond the filter media into a frame or end cap or install the gasket and the main functions of each filter adhesive are as follows.

For heavy truck air filters

For car air filters

Commercial vehicle air filter

Engineering machinery air filter

Air compressor air filter

Car air filter

Industrial dust air filter

For car and truck oil filters

For truck air filters

For air filters

For air filters

For air filters

For oil filters

For HVAC filters

| Application | PU Adhesive | Two Component Filter Cartridge Adhesive | One Component Thermosetting Adhesive | Hot Melt Glue |

|---|---|---|---|---|

| Commercial vehicles air filters | √ | √ | √ | √ |

| Passenger cars air filters | √ | √ | √ | √ |

| Construction machinery air filters | √ | √ | √ | √ |

| Cabin air filter | √ | |||

| Air compressor | √ | √ | √ | √ |

| Air cleaner & purifier | √ | √ | √ | √ |

| Vacuum cleaners | √ | √ | √ | √ |

| Hydraulic oil filter | √ | √ | ||

| Fuel filter | √ | √ | √ | |

| Spin-on oil filter elements | √ | √ | √ | |

| Eco fuel & oil filter | √ | √ | ||

| Industrial dust removal | √ | √ | √ |

If you still wonder what kind of filter adhesive is perfect for you, just contact us directly, all your problem will be solved.