- Home

- Support Center

- Production Machines

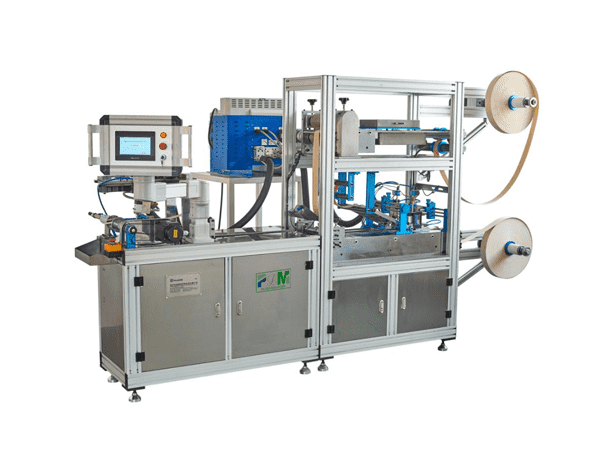

- PLPG-350

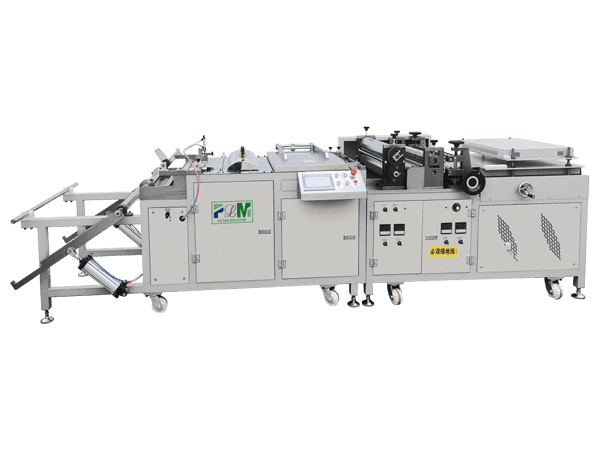

- PLM-350A

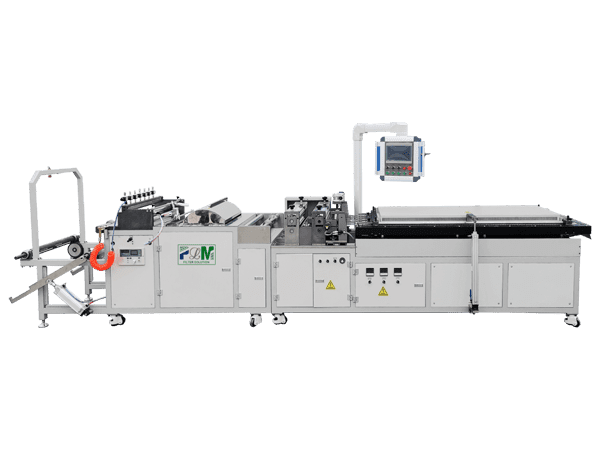

- PLGT-420

- PLGT-600

- PLGT-600N

- PLGT-1000N

- PLCZ55-600-II

- PLCZ55-800-II

- PLCZ55-1050-II

- PLCZ55-1250-II

- PLCZ55-1500-II

- Test Machines

- Auxiliary Machine

- Product Mold

- Filter Materials

- Downloads

- New Machines & Line

- Technology

- Why Four-Side Hard Edge Bonding Matters in Cabin Air Filter Production

- Why the PU Dispensing Machine Determines Air Filter Performance

- Heavy-Duty Truck Air Filter Outer Mesh Manufacturing Trends

- Advanced Filter Media Pleating Machines for Modern Factories

- Industrial Filter Paper: Key Parameters and Testing Methods

- Hot Melt Glue Types and Industrial Applications

- Filter Media Tips to Reduce Expenses

- HEPA Filter: From Primary to High Efficiency Filter Media

- Basic Knowledge of Injection Molds

- How to Select Premium Automotive Filter Paper

- Common Issues in PP Injection Molding

- Videos

One-Stop Filters Solution Designer

- Production Machines

- Process Management

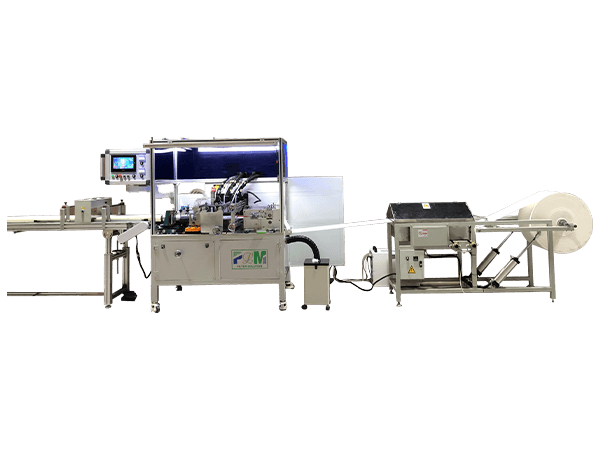

- PU Air Filter Line

- Filter Paper

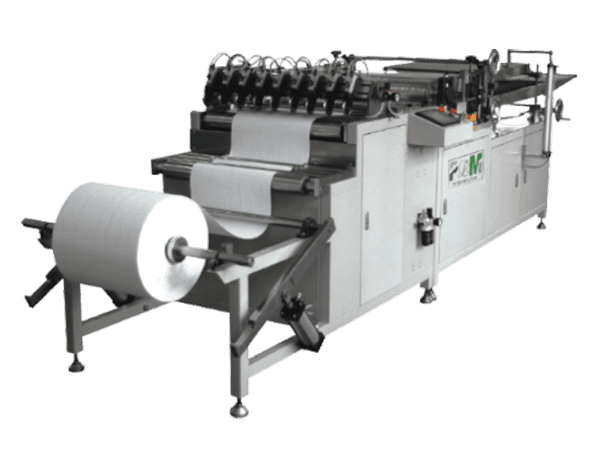

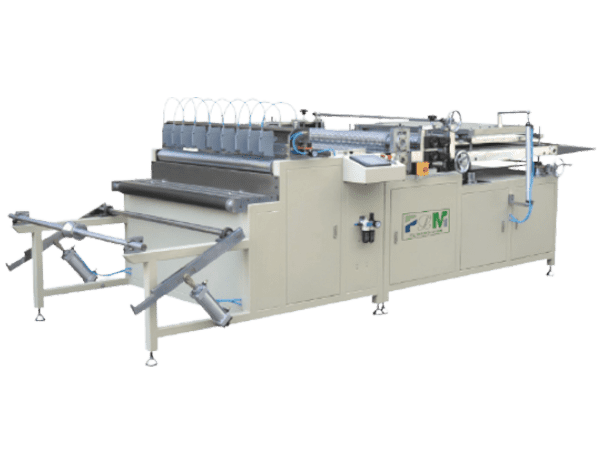

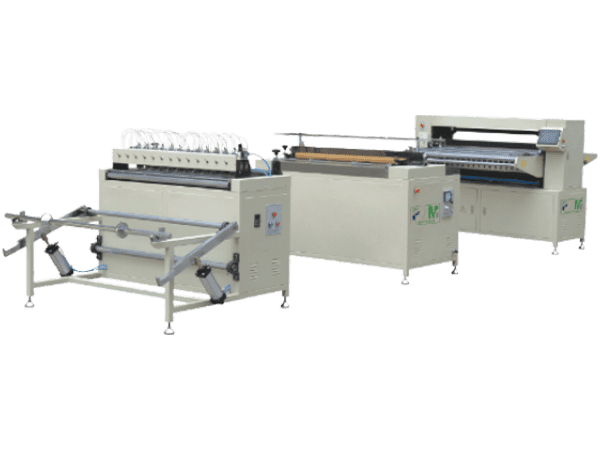

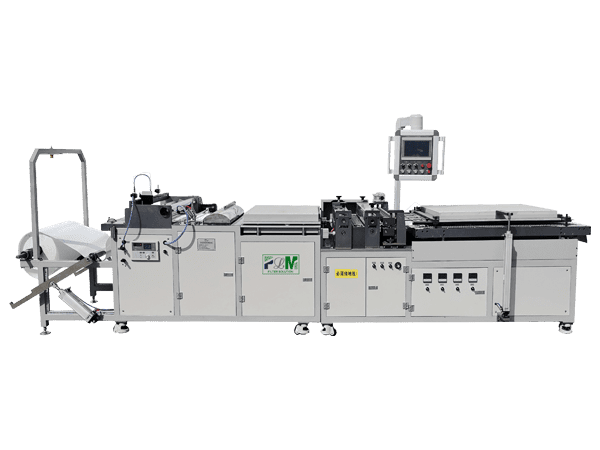

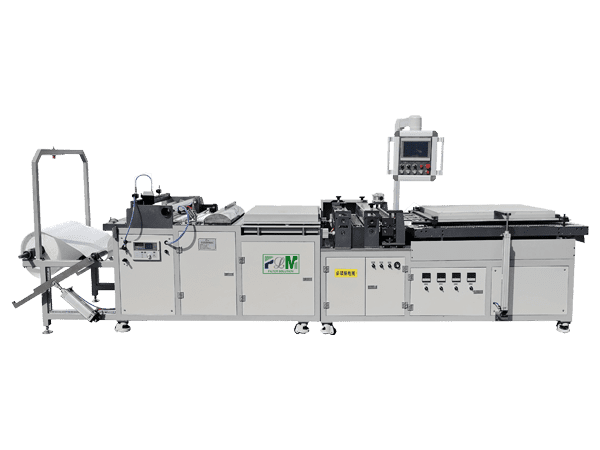

- Filter Paper Pleating

- Filter Paper Cutting

- Special Shaped Filter Cutting

- PU Frame Molding & Air Filter Assembly

- Air Filter Gluing

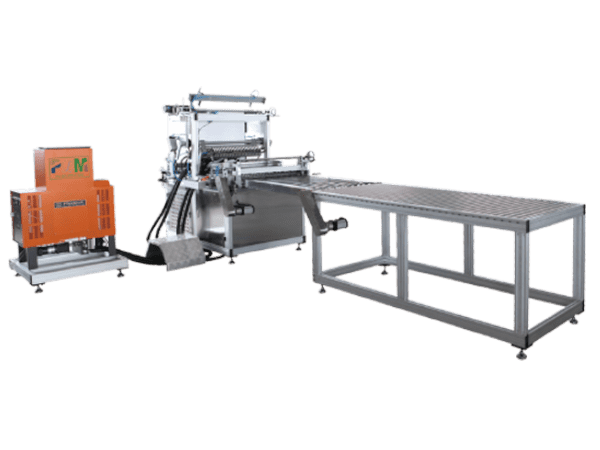

- Air Filter Curing

- Frame Trimming

- Printing

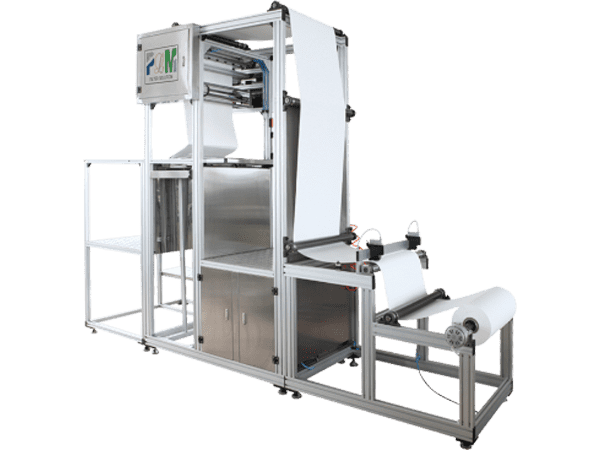

- Film Shrinking

- Convey

- PP Air Filter Line

- Toyota Air Filter Line

- Truck Air Filter Line

- Cabin Filter Line

- Spin-On Fuel & Oil Filter Line

- Eco Fuel & Oil Filter Line

- Filter Paper

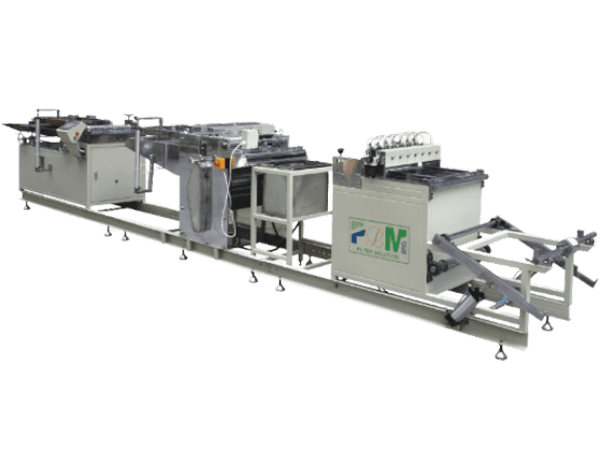

- Filter Paper Pleating

- Filter Paper Curing

- Filter Paper Cutting

- Filter Paper Bonding

- End Caps Stamping

- End Caps Gluing

- PVC End Caps and Filter Paper Assembly

- Non-Woven End Caps and Filter Paper Assembly

- Plastic End Caps and Non-Woven Filter Cloth Welding

- Plastic End Caps, Plastic Inner Tube and Filter Paper Assembly

- Hydraulic Filter Line

- Seawater Purification Filter Production Line

- Primary Medium HEPA Filter Line

- Filter Materials for HEPA Filters

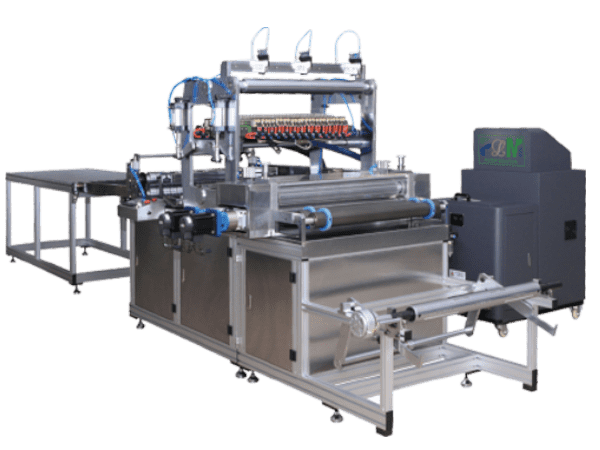

- Filter Media Compositing

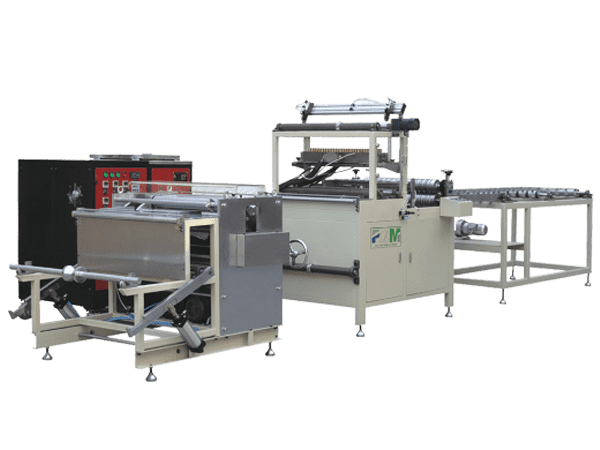

- Filter Media Pleating

- Separated Paper Corrugating

- Separated Paper Marking & Forming

- Bag-Type Medium-Efficiency Air Filter Production Line

- Bag Filter Material Cutting

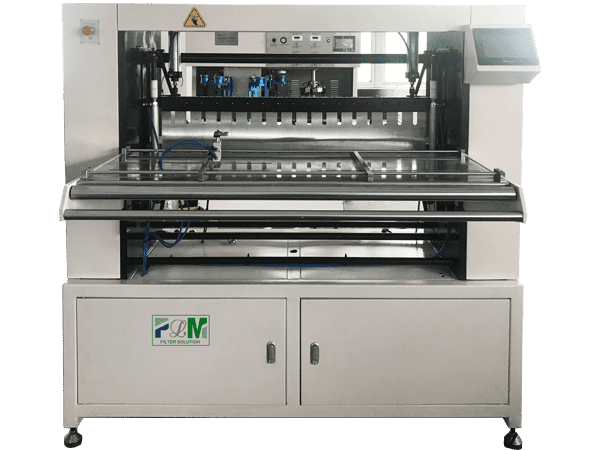

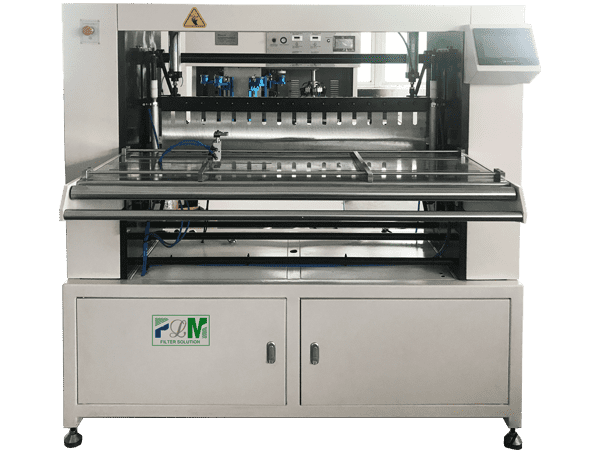

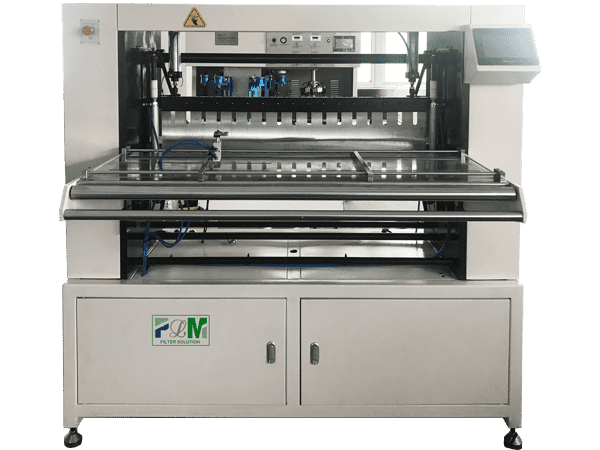

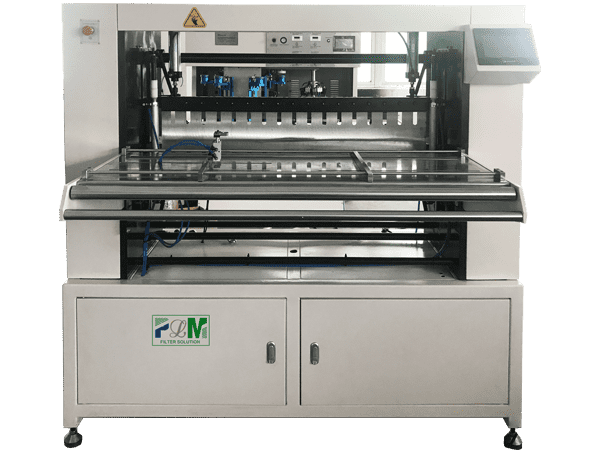

- Dispensing Machine

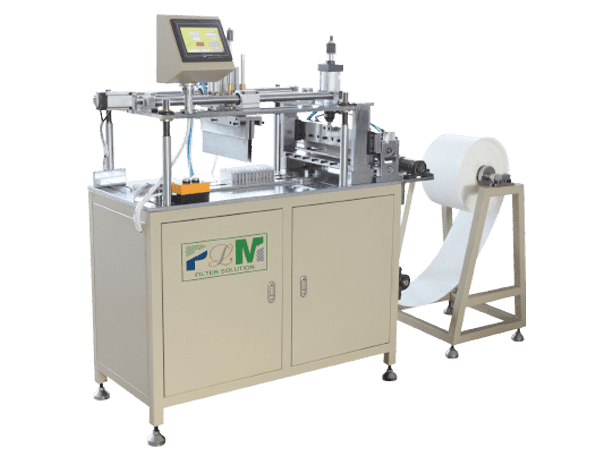

- Paper Frame Gluing

- Primary Paper Frame Filter Centerline Glue Injection

- V Bank Gluing Machine

- Trapezoidal Bag Filter Line

- Industrial Purifier & Cleaner Line

- Toyota Eco Oil Filter Line

- Honeycomb Filter Line

- Water Filter Line

- Hospital Curtain Line

One-Stop Filters Solution Designer

- PU Air Filter Line

- Total Solutions

- Customer Cases

- News

- Quality Assurance

- Technical Support

- About PLM

- Contact

search